Parameters for Live Cell Imaging

Humidity and Evaporation

ibidi's Patented Humidity Control

The ibidi Humidity Control ensures a constant and very high relative humidity (RH) level inside the ibidi Stage Top Incubator—identical to the conditions in standard cell culture incubators. This unique and patent-protected technology actively humidifies the gas mixture in a fast and reliable way before it enters the stage top incubator.

How Does it Work?

First, almost water-free gas from bottles or the laboratory line is mixed in the ibidi Gas Mixer. Then, part of the gas mixture is pumped through a heated water column for humidification. Humidified and dry air are mixed in a defined ratio before finally entering the Incubation Chamber. There, the humidity is constantly measured by a humidity sensor. This enables the comparison of the preset to the actual humidity values, allowing for feedback control of the system.

What Makes the ibidi Humidity Control Special?

Standard humidity control systems use only heated water columns to control the gas humidity in the stage top incubator. By changing the water temperature, they control the water concentration in the gas that enters the stage top incubator. Because the water temperature in the heated water reservoir changes slowly, it takes a lot more time for the humidity level to adapt. Therefore, these systems respond very slowly to disturbances like opening the stage top incubator or condensation.

In contrast, ibidi uses the following patented technology for the fast and accurate regulation of humidity: Dry and humid gas streams are mixed in a specific and actively-controlled ratio that exactly matches the preset humidity parameters.

To achieve this, the dry gas mixture from the Gas Mixer is divided: one part bubbles through the water column for humidification, the other part remains dry by flowing through a bypass. This not only makes the control much faster, but also produces much smaller fluctuations in the air humidity inside the incubation chamber. The ibidi Humidity Control's most important advantage is that it allows for very high humidity values of around "real" 90–95%, which provides the best and most reproducible environmental conditions for cells. Further, in contrast to other systems, the humidity sensor is located close to the sample (directly in the Incubation Chamber), which makes the measurement far more transferable to the direct sample/cell environment.

By using the absolute humidity rather than the relative humidity for the feedback control, the ibidi Stage Top Incubator Slide/Dish – Silver Line enables an even more precise regulation of the relative humidity (RH) inside the Incubation Chamber. Since the relative humidity is strongly temperature-dependent, determining the absolute humidity allows to compensate for any temperature differences between the humidity sensor and the sample.

The ratio of dry gas and humidified gas is determined by the actual and preset humidity, and controlled by a feedback mechanism. In a steady-state system (e.g., when both the set and the actual RH are 90%), a mixture of humidified and dry gas enters the ibidi Stage Top Incubator.

If the humidity is too low, evaporation occurs. To increase the humidity and prevent evaporation, only humidified gas from the humidification column enters the ibidi Stage Top Incubator.

If the humidity is too high, condensation occurs. To decrease the humidity and prevent condensation, only dry gas enters the ibidi Stage Top Incubator.

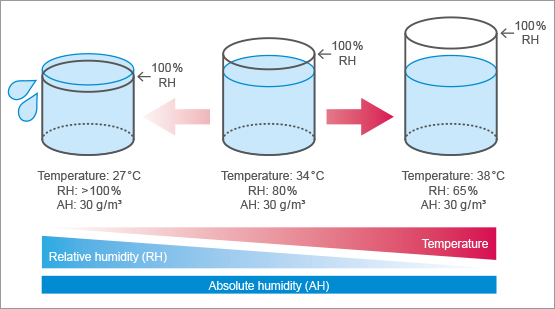

Absolute and Relative Humidity

Absolute humidity is the mass of water vapor in a defined amount of air, given in g/m³. The amount of water vapor that can be held by air is strongly temperature-dependent. Warm air can hold more water vapor than cold air.

Relative humidity (RH), given in %, is the amount of water vapor in the air at a given temperature, relative to the amount of water vapor in the air that is needed to reach saturation (100%) at that temperature.

| T [°C] | Maximum absolute humidity [g/m³] (at 100% RH) |

| 10 | 9.4 |

| 15 | 12.8 |

| 20 | 17.3 |

| 25 | 23.0 |

| 30 | 30.4 |

| 35 | 39.6 |

| 37 | 43.9 |

| 40 | 51.2 |

When the temperature increases/decreases, the maximum capacity for water vapor that can be held by the air increases/decreases as well, respectively. Even if the absolute humidity remains the same, a decrease of temperature increases the relative humidity, while an increase of temperature decreases the relative humidity. When the amount of water vapor exceeds the maximum capacity (RH>100%), condensation occurs, which causes blurry microscopy images. A low relative humidity increases the chance of evaporation of water from the liquid into the air, which must be absolutely avoided in cell culture, as you can read in the next chapter.

Why Is Humidification Important? Why Must Evaporation Be Avoided?

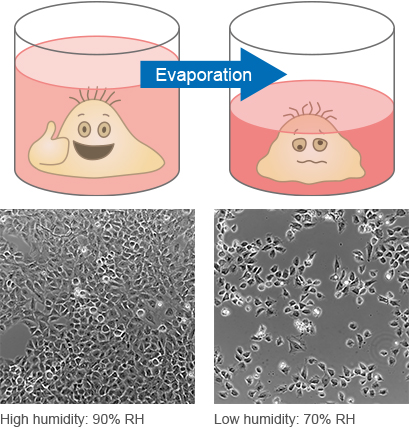

Constant levels of salts, nutrients, and other cell culture medium components are essential for reproducible cell behavior, and are crucial for consistent and reliable in vitro results. Any evaporation from the cell culture vessels increases the solute concentration (e.g., salt, waste products) in the medium in an undefined way.

This dramatically influences the vital functions of living cells, which leads to impaired cell behavior of all kinds, such as increased or decreased proliferation, up- and downregulation of gene expression, and induction of apoptosis/cell death. This happens particularly fast in low-volume cultures.

The consequences of evaporation caused by too low humidity are frequently underestimated. Cells even react more sensitively to changes in solute concentration than to changes in temperature, which can markedly distort the results. Therefore, evaporation from cell culture vessels during live cell imaging experiments should be absolutely avoided.

A constant and high level of humidity (>90% RH) in the stage top incubator is one of the keys to artifact-free results in live cell imaging.

Rat fibroblast cells cultured in full growth medium at different levels of relative humidity (RH) 48 hours after seeding. Phase contrast microscopy, 20x objective lens.

Humidity and Evaporation Control in Different Systems

In the CO2 Incubator

Cell culture vessels in the CO2 incubator are usually cultivated in an open system, and are therefore in an equilibrium with the surrounding air. In standard CO2 incubators, the humidity is created by evaporation from a water tray. Optimally, the relative humidity (RH) within an incubation system should be within the range of 90–95%.

In the Stage Top Incubator

During a live cell imaging experiment, the evaporation in the stage top incubator should be kept as low as possible, underlining the need for a reliable humidity control. A constant and high level of humidity (>90% RH) in the stage top incubator is one of the keys to artifact-free results in live cell imaging.

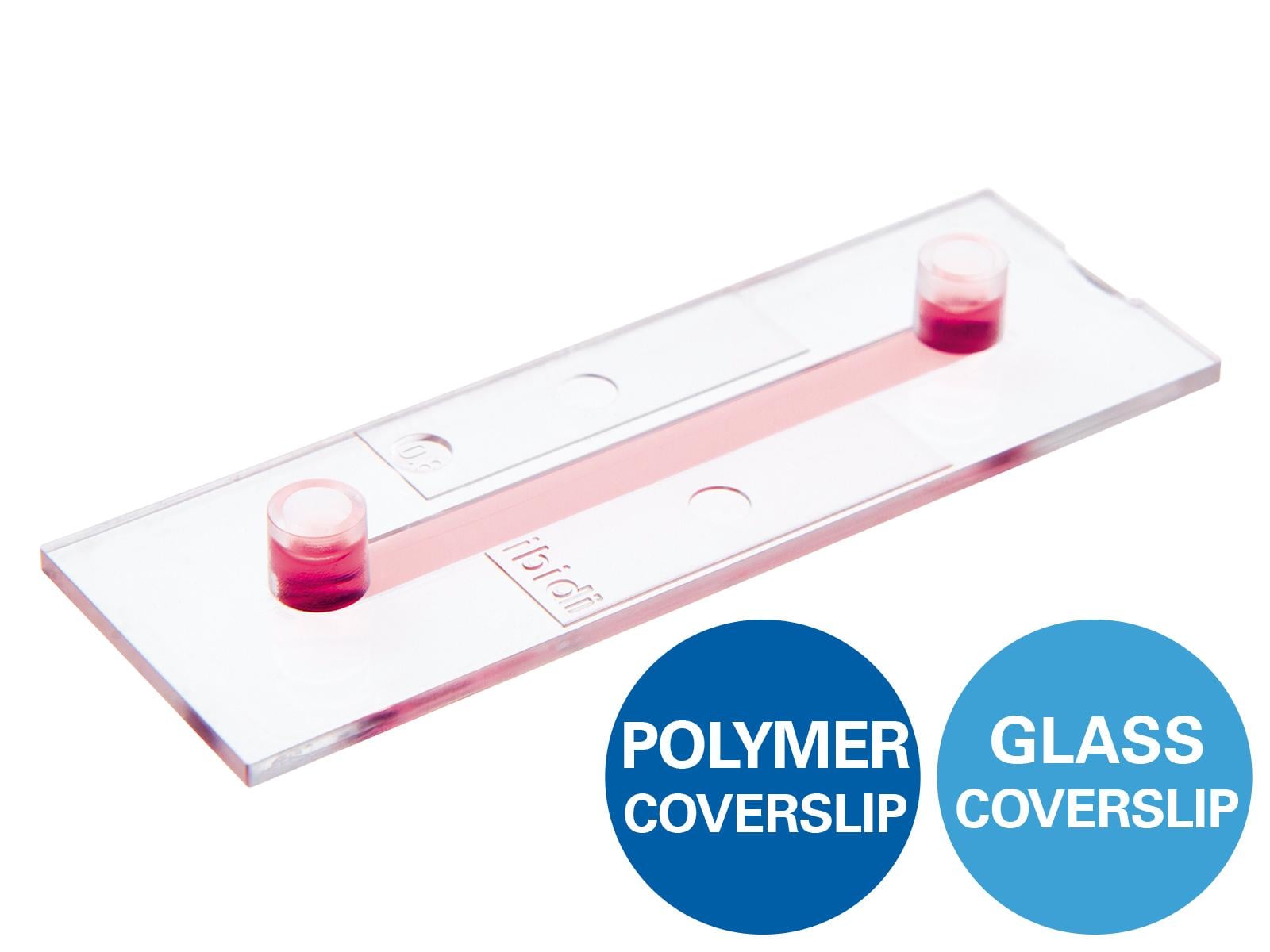

ibidi Solutions

The ibidi Stage Top Incubators provide a patented and best-in-class, feedback-controlled humidity regulation. The humidity in this system is constant and can be smoothly adapted to specific experimental needs. With a possible humidity of up to nearly 100%, the evaporation within the ibidi Stage Top Incubator is securely prevented.

The design of the ibidi μ-Dishes is optimized for low evaporation. Their lids can be set to a lock position, ensuring minimal evaporation.

For long-term studies, evaporation can be additionally reduced by using ibidi Anti-Evaporation Oil. This silicone oil is overlaid onto the culture medium, thus decreasing evaporation. Silicone oil is highly gas permeable for O2 and CO2, but effectively blocks humidity loss.

Find out more about how to avoid evaporation in the Application Note AN 12: Avoiding Evaporation (PDF).

Read on and learn more about Oxygen (O2) Levels and Hypoxia in live cell imaging.